Table Of Content

- Insert air ducts to your Sketchup model with the Engineering ToolBox Sketchup Extension

- Formula To Calculate Air Velocity In A Duct

- Calculate the CFM for Each Room

- Equivalent Diameter - Rectangular vs. Circular HVAC Ducts

- Friction Rate Calculator

- Compare top-rated HVAC pros in your area.

- Psychrometric and Coil Performance Calculator

Determining the correct tonnage HVAC unit and designing a residential duct system hasn't got to be complicated. In the guide we will break the process down and walk you through the steps necessary to design efficient climate control solutions. Now find the total duct losses for each duct and branch, that’s very easy to do simply multiply the duct length by the pressure drop per meter, in our example we found it to be 0.65pa/m. We know all the values for this so we can calculate the mass flow rate (how many kilograms per second of air needs to enter the room). If we look at the calculation for room 1, we see it requires 0.26 kg/s. So we just repeat that calculation for the rest of the room to find all the mass flow rates.

Insert air ducts to your Sketchup model with the Engineering ToolBox Sketchup Extension

For example use long radius bends rather than right angles as the sudden change in direction wastes a huge amount of energy. Most of the time, central air conditioners in homes require ducted returns. By guiding the height of the main duct, your ceiling height can be higher. Although square-shaped ducts are cheaper, they occupy more ceiling space and low ceiling height will make your home feel dark and cramped.

Formula To Calculate Air Velocity In A Duct

Properly sized ducts ensure optimal air distribution, maintaining comfortable temperature levels, and improving indoor air quality. For example, in large office buildings, incorrect duct sizing could lead to insufficient airflow to certain areas, leading to discomfort for occupants and increased energy costs. Another important unit to know is the friction loss rate of your ducts.

Calculate the CFM for Each Room

You must find the duct CFM of each room to figure out the size of air ducts to install. It’s important to do room-by-room calculations, otherwise temperatures will likely measure uneven throughout the house or office. If the total is higher than the maximum of 0.1” wc, that level of static pressure in the ductwork indicates the need for a larger blower to move the air. The air flow rate is the air volume that passes through an area in a unit of time. It is measured in m³/s, GPM, or l/s and is directly proportional to the circular duct flow velocity and the duct inside diameter. We can start to fill some of the data in, we can first include the volume flow rates for each of the branches, this is easy as its just the volume flow rate for the room which it serves.

Equivalent Diameter - Rectangular vs. Circular HVAC Ducts

Then they multiply it by 100 and divide by the total length of your system’s ductwork. TEL takes into account the pressure drops that will happen from splits, turns, and other fittings in the HVAC ductwork plan. Each fitting has an effective length that equates its pressure drop to an equivalent amount of straight duct. The Total External Static Pressure (TESP) gets measured in inches of water column (wc or iws).

Friction Rate Calculator

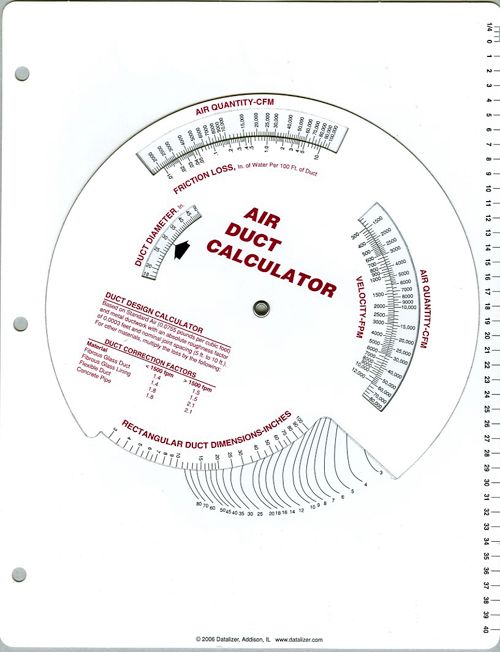

The downward diagonal lines are for velocity, the upward diagonal lines are for duct diameter. That’s why HVAC professionals have charts and tools at their disposal to make the whole process go smoother. Generally, duct design starts with identifying the airflow needed in each room. Then, we need to size and place the supply diffuser and return grille.

Ventilation Systems

If professional services are required, please consult a licensed professional engineer in your location, as building codes differ based on differing jurisdictions. The author and publisher shall not be liable in the event of damages of any kind in connection with, or arising from, the use of the information contained within this website. Still, you should always at least consult with a knowledgeable professional when you’re designing an HVAC duct system. The size of your ductwork can massively alter the comfort of your home—and the amount you spend every month to keep your house heated or cooled. HVAC units represent the largest portion of your home’s energy use, so getting those numbers right is imperative in order to save the most money on utility bills.

Compare top-rated HVAC pros in your area.

Ductwork is an essential part of your HVAC system that affects its performance, efficiency, comfort, and air quality. By following these steps, you can design your duct system to meet your needs and preferences. Always check your local codes before starting any construction project. Users can input the dimensions of their specific duct shape to obtain accurate velocity calculations.

Because an HVAC professional has access to more sophisticated tools, it’s a safe bet that their calculations will be a little bit more precise than a home handyman’s. Sizing duct work on your own can be a tedious and complicated task. Sometimes it’s best to leave it to an HVAC professional to get the perfect HVAC duct work size for your home. Below we walk through the various formulas you will need to compute, and enter into the duct calculator.

If projected velocity seems too high for the system, select the next-largest duct size. We’re going to recommend the same thing here – that you leave the maximum velocity in FPM (feet per minute) at 1500. Higher velocity would create a volume of air flow that would cause “windy” noises in your ductwork and vents and will damage them over time. If a given duct diameter produces a velocity above 1500 FPM, then using ductwork with larger diameter is another way to offset it. The software simplifies calculations for flow rate, velocity, pressure, pump duty, plant size, and recirculation systems, freeing you from tedious math and enabling you to concentrate on project design. This article aims to provide a clear, concise, and technical walkthrough of air velocity calculations, ensuring you have the knowledge needed for optimal ductwork design.

Finally, we want to consider adding a fresh air duct and check the static pressure in the duct system. Keep in mind, duct material choice also affects airflow resistance and static pressure, therefore calculations for flexible duct sizing differ slightly from sheet metal ductwork. Flex duct CFM will measure less than the airflow in sheet metal and for coated fiberglass duct board. Flex duct CFM changes based on how it’s installed, with performance drastically reduced if not completely stretched out, or with sharp turns and twists.

This allows the air to smoothly change direction and thus there is no sudden increase in static pressure and the air flow rate to the rooms has dramatically increased. The second thing to consider is the material being used for the ducts, and the roughness of this material as this causes friction. For example, if we had two ducts, with equal dimensions, volume flow rate and velocity, the only difference is the material. One is made from standard galvanised steel the other from fibreglass, the pressure drop over a 10m distance for this example, is around 11 Pa for the galvanised steel and 16 Pa for the Fibreglass. This free ductulator calculates the exact duct size (round and rectangular) for the given friction rate, duct type, and amount of airflow. It will automatically adjust the size to keep from exceeding the maximum Manual D velocities for residential duct systems.

No comments:

Post a Comment